Delivering Fitz Frames’ 3D-Printed Glasses for Kids Through Innovative Product Development

Executive Summary

Wizeline worked with Fitz Frames, a Los Angeles-based company printing 3D custom glasses for kids, to develop an application to provide customers with an enhanced eyeglass-fitting experience.

Wizeline brought engineering expertise in augmented reality (AR) and iOS development to help Fitz Frames solve the challenge of outfitting young kids with glasses without a trip to the optometrist in less than a year. It is now the only provider offering facial measurement and custom style at an affordable price point. The Fitz Frames app is available for download on the App Store.

Read more to see how the Wizeline team successfully completed the product development process from start to finish.

Background

Today, nearly 20 million children in the U.S. wear prescription glasses, and 1 in 20 preschool-aged children need corrective glasses. What’s driving these high numbers? Besides the proliferation of devices and potentially harmful screen time, screenings have increased for detecting early vision problems.

If you think finding the right pair of glasses is tough as an adult, these challenges are only amplified for kids. For Fitz Frames founder, Heidi Hertel, shopping for glasses for her kids was not fun.

“I have three kids, and two of them have worn glasses since they were really little. They were only two or three years old when they first needed glasses, and I started trying to find the right option for the pretty serious prescriptions they needed.”

Finding frames with the right color, style, and fit was nearly impossible, especially in one store visit. Adding in kids’ short attention spans and a parent’s busy schedule, Hertel quickly saw that families were only settling for good enough.

And what happens after they settle on a pair of glasses? Kids often break these glasses, lose them, or quickly outgrow them. And finding an exact replacement? Brands often discontinue styles or produce limited sizes, forcing parents to start the painful process all over again.

The Opportunity

Hertel joined the board for Vision to Learn in Los Angeles, a nonprofit that conducts mobile eye exams and provides access to families in need. She learned more about the challenges around kids’ glasses and researched beyond what doctors and boutiques could offer. She quickly discovered that no one was addressing the problem. “Kids became attached to their glasses,” said Hertel. “It becomes part of their identity and how they see the world.”

Hertel met Fitz Frames’ CEO, Gabe Schlumberger, at their children’s school. Schlumberger’s son, Lucas, also needed glasses at an early age, and he was experiencing similar frustrations and challenges.

Hertel and Schlumberger teamed up to provide an alternative for parents and their kids. They asked themselves, what if kids could create glasses in a fun and easy way with their parents? What if parents could use the latest technology to ensure glasses fit more comfortably and allowed their kids to see better? What if the perfect fit came out of the box and delivered directly to your door? And what if they didn’t have to start the process over every time their kid needed a new pair? The team got to work and soon discovered they needed help executing their game-changing vision.

Enter Wizeline: Implementing the Right Team and Framework

Wizeline partners with leading enterprises and startups to build scalable engineering teams that include a range of expertise areas and technical functions. In addition to sourcing the right technical chops, Wizeline established processes and working cadences that suited the growing startup’s needs and integrated the team into Fitz Frames’ culture and team dynamic.

Wizeline brought engineering expertise in augmented reality (AR) and iOS development to best achieve Fitz Frames’ product objectives. Unlike conventional partners, Wizeline considers the product development process end-to-end, not just the engineering component in isolation. The initial Wizeline team included:

- One dedicated project manager

- Four iOS developers

- Two data engineers

- Three backend engineers

- A DevOps engineer

- A QA engineer

- One savvy tech writer

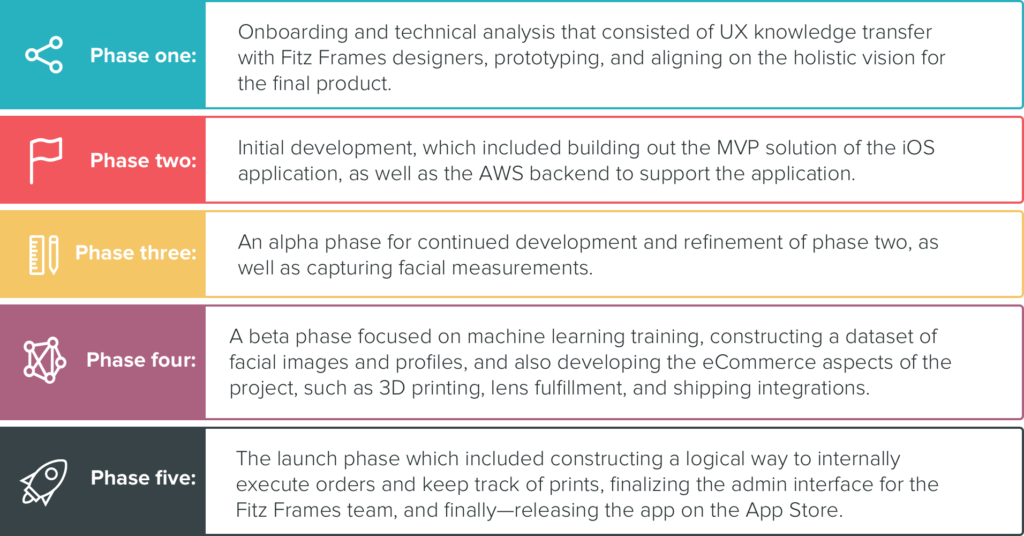

The team approached the project in five different phases.

Enabling Integrations With Cloud-based Solutions

The Fitz Frames project employed Amazon Web Services for platform management, security, content, and implementing core operations like printing and shipping.

The platform implemented a microservices approach using AWS Lambda services. This enables the platform to be managed and maintained as a collection of secure and independent modules. The backend uses GraphQL through an Apollo Server Lambda, accessed using the Amazon API Gateway instance. The application uses an Amazon Cloudfront instance to deliver the Fitz content to end-users.

The platform implements multiple tiers of security protocols: AWS Identity and Access Management (IAM) as security; developer access to the platform is managed through the inherent IAM feature of AWS. Amazon Virtual Private Cloud (VPC); network access restrictions to and within the platform are managed through the inherent VPC feature of AWS. Amazon Cognito; end-user and administrator access to the platform is managed through the Amazon Cognito service in AWS.

In the 3D printing module, AWS DynamoDB verifies that the prescription, measurements, and payment are valid and triggers a Printing Lambda in the backend.

In the third-party shipping label modules, AWS DynamoDB verifies if the 3D printing and lens manufacturing process for the order is complete and triggers the Shipping Label Lambda in the backend.

The Fitz application also uses DynamoDB to store all the events in the application and Amazon RDS to store information such as account details and order history in its data model.

Why Wizeline?

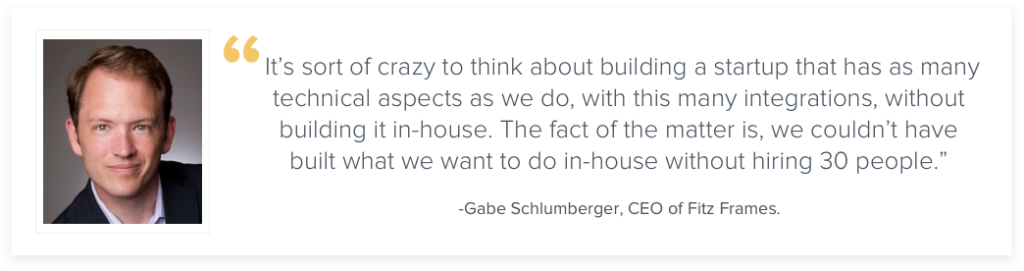

“It is sort of crazy to think about building a startup that has as many technical aspects as we do, with this many integrations, without building it in-house,” said Schlumberger.

“The fact of the matter is, we couldn’t have built what we want to do in-house without hiring 30 people. It takes lots of nuances to implement the complexity of measurement and glasses resizing—all of which had been unsolved by the industry so far. This was not off-the-shelf technology. It needed to be integrated with manufacturing, be HIPPA compliant, be able to send 3D model files and order information to a server, and connect to our lens supplier.”

When asked about the value that Wizeline brought to the project, the Fitz Frames team pointed to the breadth of experience and talent available to tackle a problem of this scope. “Wizeline is big enough to provide that breadth of experience, but still small enough to help from inception to actual execution across the board,” said Schlumberger.

Katie Basset, VP of Product and Operations at Fitz Frames, noted that it was nice that Wizeline is large enough to cover a majority of Fitz Frames’ development needs, but without a lot of the bureaucracy that usually accompanies large development firms. “The bench is broad enough that there was someone from Wizeline that could be brought in at every phase, from user interface designers to AI experts.”

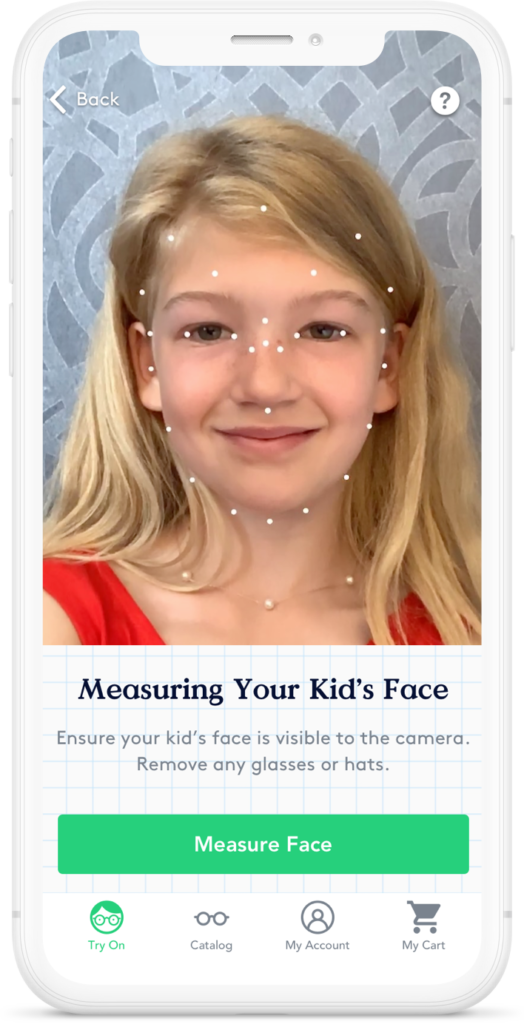

A Digital Solution for Custom Glasses

The Fitz Frames app provides customers with an enhanced eyeglass-fitting experience using advanced facial mapping to take accurate measurements from easy to snap in-app photographs. The app allows customers to try on glasses virtually with different frames from the comfort of their home, removing the hassle of in-store shopping while also offering an improved fit.

The app experience was designed to encourage kids to take charge of their own experience, exploring a catalog of six frame shapes and eight colors to create unique customized glasses and sunglasses explicitly designed for them. Customers also have access to the latest in eyewear technology, with options to select blue-light lenses.

Once frames are selected, the customized glasses are printed with 3D laser printers at the Fitz Frames factory in Youngstown, Ohio. Tailor-made to reflect the unique contours of each child’s face, Fitz Frames are also outfitted with snap-fit hinges — an upgraded design technique that eliminates the risk of loose screws, adds a layer of playability, and provides a necessary and welcome solution to (all too frequent) broken glasses for kids. Customers can manage individual profiles for each kid, allowing them to track their orders, update prescriptions, and view previous styles and selections.

In addition to individual purchases, Fitz Frames also offers a subscription option, providing members with two sets of frames and lenses for $185 per year. To reduce stress and increase accessibility, Fitz Frames will cover the cost of replacement frames for subscribers who exceed the two pairs included in their membership, so they are only responsible for the cost of replacement lenses and shipping.

Invaluable Outcomes

Initially, the Fitz Frames team estimated that development would take 10 weeks but quickly realized it would take closer to 22 weeks to solve the full scope of the problem they had set out to tackle. “The biggest KPI was a great product, and we’re 99% there,” said Hertel.

The team also counts its ability to go from idea to launch with zero in-house engineers as a significant win. For a non-engineering team, the value and rarity of working with a technology partner they could adopt as their own are not lost on Schlumberger and team: “You usually see one of two things: a couple of guys in a shop somewhere, they’re enthusiastic, but they can’t scale. Or it’s a giant corporate entity, and you only interact with your project manager and never talk to the engineers. It was refreshing that everyone at Wizeline was incredibly solutions-oriented. It took some time to get up to speed, but everyone understood that we wanted to make glasses kids would love and want to keep. Everyone got that, from QA to frontend.”

2020 and beyond

Fitz Frames had a long to-do list post-launch, focusing on scaling operations and partnerships, expanding beyond iOS, and ultimately, solving glasses for parents and kids. There is a Fitz for every face, and the goal is to be in every household for prescription, sunglass, or blue light blocking needs.

Delivering the highest accuracy in measurement and fit required optimizing for devices with optimal camera technology. As a result, Fitz Frames is now available for download on iPhone 10 and above in the App Store. Please visit FitzFrames.com for more information or to scope out a pair of custom glasses for your family.